32oz Heaviest Jeans in the World!

If anyone was to ask me « what is your favorite pair of jeans that you have ever created? »… my answer is our 32oz selvedge denim jeans… The heaviest pair of jeans ever made! We have worked to build this jean for 2 years and I can say with certainty that it was by far the most difficult production challenge we have ever overcome. Most people ask me « why the hell would you make a pair of jeans that is so heavy and uncomfortable? » and it’s a fair question… I often reply with an analogy « Why would someone climb mount Everest? » It’s not comfortable to do, its not easy, nor is it inexpensive… people do it so they can say they conquered the tallest mountain in the world. I find that human beings are fascinated by anything that is a superlative. Well, these jeans are my denim superlative.

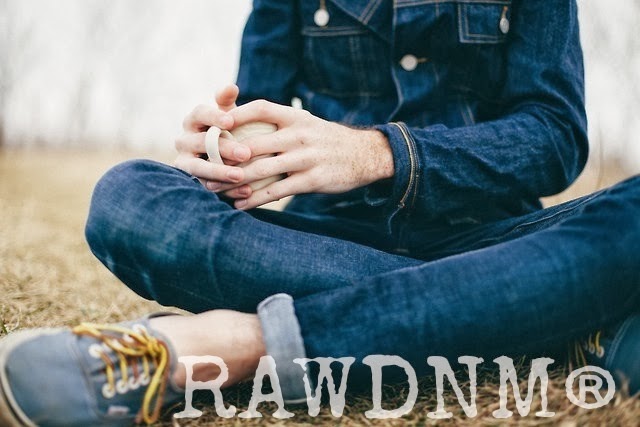

From weaving the denim to cutting and sewing to installing the 15oz leather patch, this process has been a marvel of Japanese production skills. Without further blabbing, here are the photos of the final result…

138 pairs total were made and are available now at fine retailers worldwide! We may never be able to make these again so if you want a pair, you’ll have to act fast! So heavy and rigid, the jeans can easily stand on their own…

I’m often asked if the jeans are actually wearable. The answer is YES! I’ve worn a pair for a few days and it was doable, but I’m pretty bony and my hips were a bit marked up afterwards. In this photo below you can see one of the great staff members at colette boutique in Paris wearing his pair of 32oz jeans. They look amazing on him! He says after just 2 days of wear they are broken in and comfy. (I think he may be tougher than me.) Notice how he’s got a thick belt over the super thick patch!…

Here is 3 pairs of 32oz jeans next to 9 pairs of 11oz jeans!

I thought it would also be fun to share some photos of the actual sewing process, so here goes!… These photos are not in any particular order and I have 3000 photos of the production, so I just randomly chose a few…

The amount of hammering and ‘bashing’ involved in order to make the seams sew-able was extraordinary! A 2-sided mallet and the back of a screwdriver were both used to tame the beast that is 32oz denim…

One of the most difficult parts to sew is the feed-off center back yoke seam. That’s the point where several pieces are joined together, and you can see in the 4th photo below how thick that seam is. It’s almost a full inch thick! Crazy. This operation is always done by the most skilled worker. Good thing the Union Special held up as well as her fingers!

Struggling to turn a semi-finished pair outside-in… (It’s even difficult to just cuff these jeans!)

Hmm… how in the world are we going to sew the buttonhole?…

…With man-hand-power, that’s how!…

Laser-guided rivet installation…

Carefully sewing the woven taffeta label over a huge bump where the center yoke seam meets the waistband…

The final cleaning and snipping of any loose/extra thread. How rad are these 2 ladies?!…

Ok, I will admit that I put in this photo below because the girl is cute… Kawai!

Some extra photos for fun…

Well that’s it for now… If you are lucky/brave enough to have bought one of these masterpieces please do email me the photos. This denim should fade really beautifully as well! If you are thinking of buying a pair, just remember we like to joke… « Guaranteed uncomfortable or your money back! »

http://nakedandfamousdenim.com/fr/

No comments:

Post a Comment